- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Flotation Reagents

Jun 08, 2016 · Usual Method of Feeding: Whether in dry or liquid form. A large number of reagents are available in liquid form and naturally are best handled in wet reagent feeders, either full strength or diluted for greater accuracy in feeding. ... A frother and promoter for flotation of potash salts, barite, magnesite and various other nonmetallics.

Method of processing barite Beneficiation process ...

A combination of classifiion (initially screens to remove the coarser 'impurities', then hydrocyclones to remove the finer 'impurities' with some barite loss), gravity (calcite/fluorspar/silica from barite and sulphides from barite) and flotation (oleic acid/alkyl sulphonates/sulphates with sodium silie as the dispersant and neutral to alkaline pH barite is depressed at acidic pHs).

fluorite processing technology

Nov 13, 2019 · A process for the preparation of fluorspar flotation method, the crude intermediate product produced with oleic fatty acids or mixed fatty acids as raw materials, added thereto weight of the fatty acids of 3% to 15% by weight of concentrated sulfuric acid, so that the occurrence of sulfatedreaction, again in the reaction product by weight of ...

Barite Quality Improvement Method

The method is realized by a flotation at presence of a fatlyacid collector, in which the floatation barite concentrate is additionally treated with a reactant for modifiions of the barite particles surface. of waste rock under the action of guatajiagua component and their discharge from discharge thickener is getting high qualityA ...

Barium

Barium is a chemical element with the symbol Ba and atomic number 56. It is the fifth element in group 2 and is a soft, silvery alkaline earth of its high chemical reactivity, barium is never found in nature as a free element.. The most common minerals of barium are baryte (barium sulfate, BaSO 4) and witherite (barium carbonate, BaCO 3), both insoluble in water.

Home

Phosphorus ore flotation process. detail > Barite. Baryte mineral processing flowsheet. detail > Kfeldspar. Potassium feldspar process flowsheet. detail > Graphite. Graphite mineral processing flowsheet. detail > Quartz sand. Quartz sand mineral flowsheet. detail > Fluorite.

Lauryl Phosphate Flotation Chemistry in Barite Flotation

Barite has numerous appliions including barium mud for oil well drilling, manufacture of elemental barium, filler for paper and rubber industries, and contrast material for Xray radiology for the digestive system. Currently, froth flotation is the main method for the beneficiation of barite using fatty acid as a typical collector. In this research, it was found that lauryl phosphate is ...

Barite mineral processing technology symposium by 9X Minerals

Feb 13, 2017 · Barite mineral processing methods According to the ore properties, mine scale and use of different, there are gravity separation and flotation methods. Gravity separation, including washing ...

Barite Beneficiation Process

Flotation method must be used for the separation of ores with fine inlaid particle size and tailings of gravity separation. There are two kinds of flotation processes for barite: positive flotation and reverse flotation. The purpose of reverse flotation is to remove alkali metal sulfide.

Flotation Recovery of Barite from Ore using Palm Bunch ...

Froth flotation of Azara barite ore was carried out using a mixture of available raw materials, the burnt empty palm (Eleasis guineesis) bunch solution, and analytical grade palmitic acid as collector, sodium silie as depressant. Optimum recovery was obtained at collector concentration of moles litre1. Energy Dispersive Xray spectrophotometric analysis of the feed ore and concentrate ...

Barite

The flotation mills typically utilized barite ore containing about 50 percent barite. The result was a concentrate composed of 92 to 94 percent barite. Total production of Arkansas barite concentrates is 9 million short tons ( inclusive) – 8 million short tons from the Chamberlain Creek deposit alone valued at ~ 70 million dollars.

Google Fordító

A Google ingyenes szolgáltatása azonnal lefordítja a szavakat, kifejezéseket és weboldalakat a magyar és több mint 100 további nyelv kombinációjában.

Ore

Ore is natural rock or sediment that contains one or more valuable minerals, typically containing metals, that can be mined, treated and sold at a profit. Ore is extracted from the earth through mining and treated or refined, often via smelting, to extract the valuable metals or minerals. The grade of ore refers to the concentration of the desired material it contains.

Stokes Law

If barite particles finer than 10 ... flotation (aero or air induced), and electrostatic or electrodynamic separation. Examples of destructive methods include separation by dissolution ... The Andreasen pipette method is a British Standard test method and is fully described in [24].

Five Barite Mining Processes and Common Barite Mining ...

Jun 05, 2020 · The flotation method must be used for the separation of fine barite ore and gravity separation tailings. The main barite flotation processes are positive flotation process and reverse flotation process, in which the purpose of the reverse flotation process is to remove the alkali sulfide.

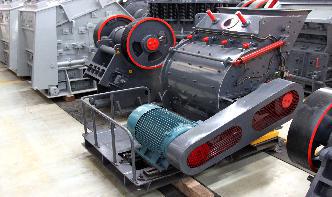

Mineral Processing Flowsheets

Mar 08, 2016 · The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants. Metallurgical data are shown in these flowsheets which incorporate Crushers, Grinding Mills, Flotation Machines, Unit Flotation Cells, and Selective Mineral Jigs as well as other standard milling equipment. The Flotation Machine, the Selective Mineral Jig and ...

barite

Mar 19, 2020 · Barite flotation generally USES anion collector: fatty acid salt, petroleum sulfonate or sulfate, etc. Table 1 Main processing Methods of Barite. 2. Process Flow. Process flow of residual barite ore. Eluvial barite ores are generally separated by gravity separation, that is, jigging or other gravity separation methods are used to select ...

LookWAYup

definition of senses, usage, synonyms, thesaurus. Online Dictionaries: Definition of Options|Tips

barite processing

Apr 09, 2021 · Direct flotation method. The flotations used in the baritequartzcalcite type ore mainly include the following: First, add the inhibitor to inhibit the gangue minerals (such as quartz, calcite). Then, add the anion collector under the weak alkaline condition. And the barite concentrate can be obtained by roughing and 35 times of concentrating.

Archimedes Principle

Another method for measuring lapillisized particles is gas (He) pycnometry, which is usually used for density measurements and is based on gas displacement principle (eg, Klug et al., 2002). For uncoated porous particles, both Archimedesbased methods and gas pycnometers measure the skeletal volume, which is the particle volume without ...

Selective Separation of Fluorite, Barite and Calcite with ...

Fluorite, barite and calcite are important industry minerals. However, they often coexist, presenting difficulty in selectively separating them due to their similar surface properties. In this study, valonea extract and sodium fluosilie were used as depressants to selectively separate them by flotation, with sodium oleate as the collector.

Summary of Fluorite Ore Flotation Process

Apr 24, 2019 · In general, the flotation process of the barite type fluoride ore is divided into two steps, one is combination flotation that obtains the combination of concentrate both of barite and fluorite, another is flotation that separation the barite and the fluorite from the combination concentrate. Flotation of the first step: Na2CO3 as the ...

Selective flotation and adsorption of ilmenite from titanaugite by a novel method: Ultrasonic treatment Powder Technology, 2020, 363: 3847. (IF= ) ; Shuai Fang, Longhua Xu*, Houqin Wu, Yanbo Xu, Zhoujie Wang, Kaiqian Shu, Yuehua Hu. Influence of surface dissolution on sodium oleate adsorption on ilmenite and its gangue minerals ...

Copyright © .CMichineAll rights reserved.خريطة الموقع